|

|||||

FORMER GERMAN SUBMARINE TYPE IX-C |

|||||

SHAFTING AND BEARINGS |

|||||

SUMMARY |

|||||

| The shafting and clutching arrangement for the Type IX-C is that required for a direct drive vessel. Standard practices are used in the design and layout of the component parts of the system. | |||||

| A stern tube gland tightening arrangement similar to an experimental one on U.S. submarines has been installed permanently on this class of vessel. | |||||

May, 1946 |

|||||

PORTSMOUTH NAVAL SHIPYARD, PORTSMOUTH, N. H. |

|||||

- 1 - |

|||||

9C-S43 |

||||||||||||||

C O N F I D E N T I A L |

||||||||||||||

SHAFTING AND BEARINGS |

||||||||||||||

| 1. GENERAL DESCRIPTION | ||||||||||||||

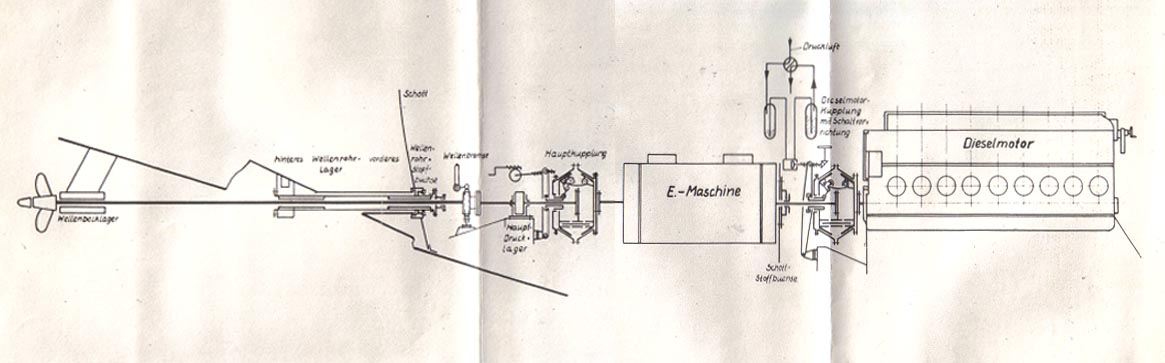

| A twin-screw propulsion arrangement is installed on the IX-C. The shafting setup is shown on Plate I. Each of the diesels when running at rated speed (470 RPM) transmits 2200 H.P. to the main shaft. The friction clutch forward of the main motor is operated by pneumatic hydraulic action while that aft is hand-operated. The main propeller thrust bearing and shaft brake shown are both of standard design. The stern tube and strut bearings are inlaid with lignum vitae. The outboard shaft is rubber-covered; that part between the stern tube and strut bearings is wrapped with light wire. | ||||||||||||||

| 2. INDIVIDUAL COMPONENTS | ||||||||||||||

| a. Shafting | ||||||||||||||

| The shaft line runs at an angle of 0°40' to the centerline and 0°0 to the base line. The main and propeller shaft dimensions are as listed below: | ||||||||||||||

|

||||||||||||||

| The shafts are made from a martinsitic forged steel with the following characteristics: | ||||||||||||||

|

||||||||||||||

| b. Stern tube | ||||||||||||||

| The stern tube consists of a forward and after cast steel bearing connected by a steel tube. The bearings have bronze bushings inlaid with lignum vitae on the lower third of the bearing. A circulating water connection is led to the bearing for flushing and cooling purposes. A standard stuffing gland is employed for the insertion of packing rings. The gland is tightened by means of a spur gear arrangement which insures uniform tightness of all tightening bolts. | ||||||||||||||

- 2 - |

||||||||||||||

9C-S43 |

||

| The designed stern tube and strut bearing clearance is 1 mm (.040 ins.); operating instructions available call for renewal after 3.5 mm (.140 ins.) wear. | ||

| c. Main thrust bearing | ||

| A standard main thrust bearing is installed employing ten individual shoes and capable of absorbing 33000 lbs. thrust at 500 shaft RPM. It is self-lubricated and has a built-in cooling system for cooling the lubricant. The gearing for the shaft revolution indicator is built into the thrust bearing housing. | ||

| d. Main and diesel couplings | ||

| Standard cone type friction couplings are used. To provide the quick operation necessary for uncoupling of the diesel from the main shaft a combined pneumatic-hydraulic setup is employed. This consists of a hydraulic oil cylinder operating in conjunction with an air on oil cylinder, a common German practice. Hand operation is also provided for emergency use. The main coupling is operated by hand crank arrangement. Both of the units are designed to function at a maximum torque of 94,000 lbs. ft., equivalent to 25% overload. Operating instructions state that the clutches should not be engaged when turning the shaft above 350 RPM. They may be disengaged at any RPM. | ||

| 3. CONCLUSIONS | ||

| The shafting arrangement is standard in nature for a direct drive submarine. The major deviation from normal U.S. practice is in the use of lignum vitae for the lower third of the strut and stern tube bearings. This provides a conservation of lignum vitae but results in an undesirable "combination" bearing. | ||

| A similar tightening arrangement for the stern tube gland to that installed on the IX-C has been installed on some U.S. submarines and is recommended for adoption on all submarines, especially inasmuch as it provides a ready means for changing the pressure on the packing under varying operating conditions. | ||

- 3 - |

||