|

|||||

FORMER GERMAN SUBMARINE TYPE XXI |

|||||

VENTILATION, AIR PURIFICATION AND OXYGEN RENEWAL |

|||||

SUMMARY |

|||||

| The ventilation system on the XXI is arranged like that on the preceding types but is designed to obtain lower operating sound levels. | |||||

| The capacities of the air purification and oxygen renewal system have been materially increased over that provided on the type IX and other earlier types. | |||||

| The air conditioning capacity has been increased to a lesser degree. The system has been designed with means for interchanging the functions of the condenser and air conditioning coils, thereby providing a secondary means for heating the ventilating air within the vessel. | |||||

March, 1946 |

|||||

PORTSMOUTH NAVAL SHIPYARD, PORTSMOUTH, N. H. |

|||||

- 1 - |

|||||

|

|||||

| 1. Introduction | |||||

| The various systems under discussion as existing on the IXC have been described in Report 2G-9C-S38. An air conditioning system, similar in many respects to that on the XXI, has been installed on the IXD2 and is described in report 2G-9D2-S38. In addition, the installation and operation of the battery ventilation on the XXI is described in the NavTech Report No. 310-45. This present report will go into detail on the type XXI systems only wherein they differ from those installed on the preceding vessels and wherein amplification of the material covered in the NavTech report is considered desirable. | |||||

| 2. General Description | |||||

| Although the same general arrangements of the ventilation, oxygen and CO2 removal systems on earlier types of German submarines have been retained on the type XXI, certain modifications were made to the systems to meet the changed construction and operating requirements of this vessel. | |||||

| Because of the increased space within the pressure hull, larger main duct sizes were permitted. The ventilation system installed was designed using lower duct velocities and vent blowers of lower rated speed than on previous types. Maximum duct diameters are approximately 12-3/8" (I.D.). This results in a comparatively quieter ventilation system. | |||||

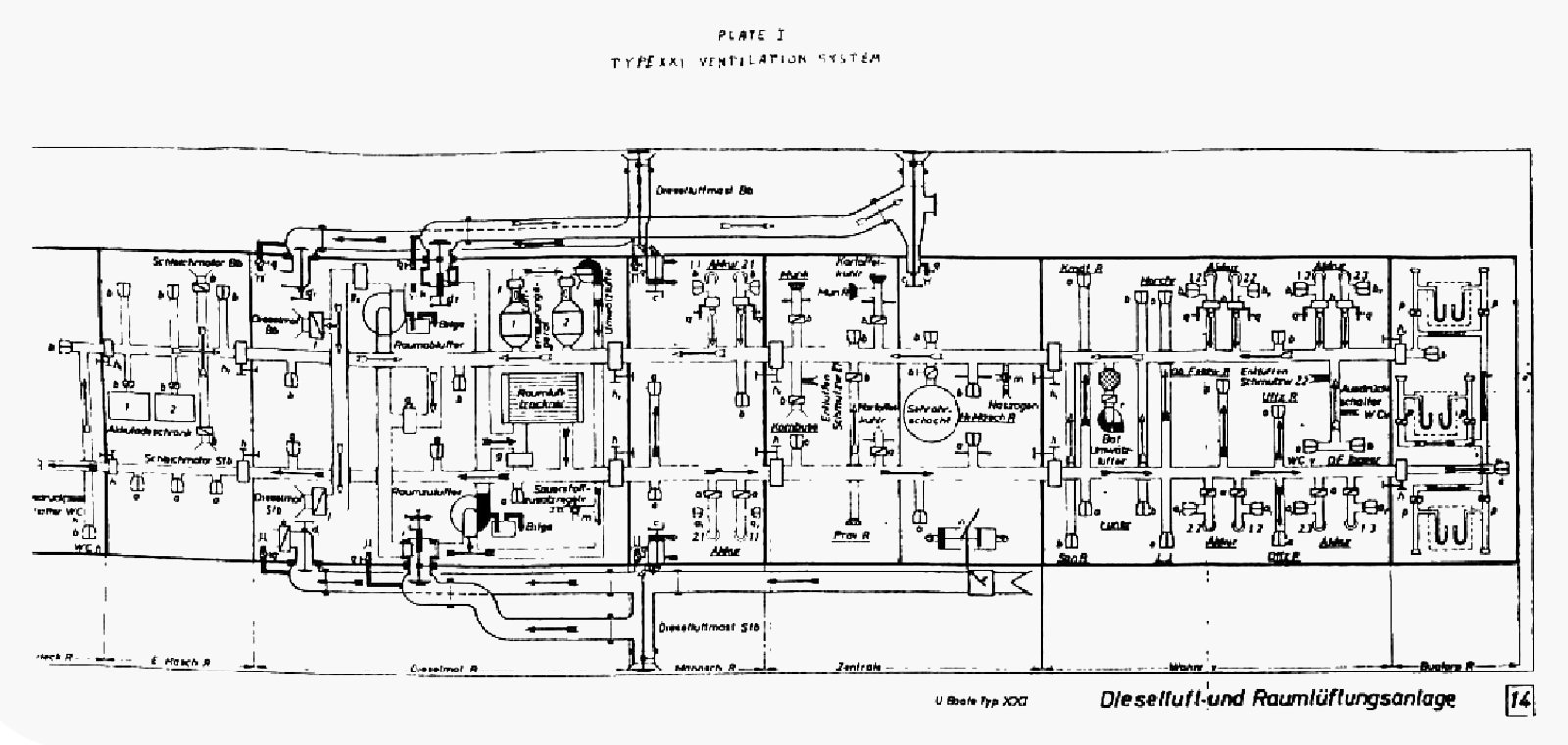

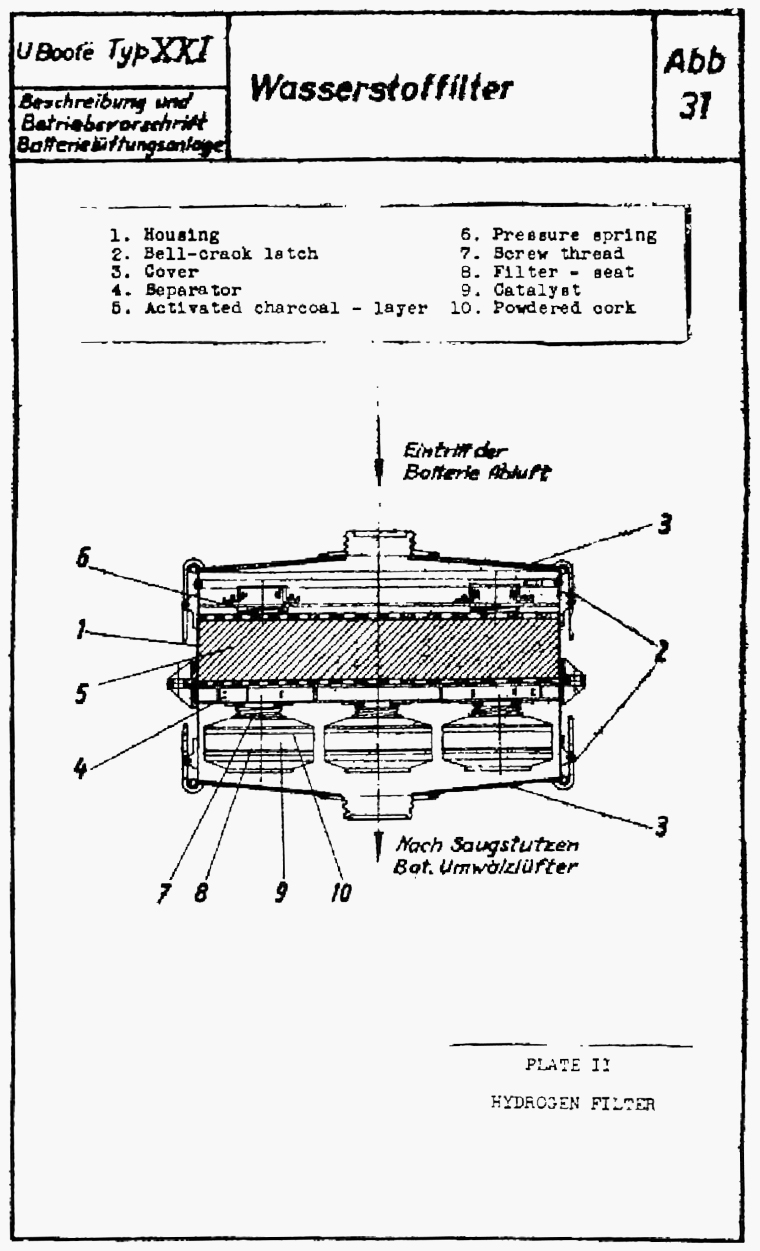

| Because of the large battery, additional exhaust ducts and added precautionary measures were necessary. On the XXI the ratio of battery space to pressure hull volume is much higher than for the previous types of submarines. Also the type of battery used has a marked tendency to evolve hydrogen (at an appreciably greater rate than on a U.S. submarine battery). These two factors have made it necessary to be able to limit the hydrogen concentration within the vessel when forced to dive while charging batteries. To accomplish this, a hydrogen filter and small recirculation blower has been installed. See Plate I. The filter, Plate II, has an activated carbon element to reduce the moisture content of the air, and a series of catalyst chambers in which the hydrogen reacts with the oxygen in the air. This filter accomplishes the same purpose as does a hydrogen burning arrangement. However, it will remove hydrogen at lower concentrations than that necessary for a combustible mixture in air alone. | |||||

- 2 - |

|||||

|

|||||

| Because of the longer submergence periods permitted through the use of the larger battery and schnorchel operation, additional capacity was built into the oxygen and CO2 removal systems. The capacity is based on the requirement of 50 men during 150 hours of use. | |||||

| 24 oxygen bottles, each containing 1.77 cu. ft. at 2130 p.s.i. pressure, were placed on board. In addition, a total of 25 oxygen generating cartridges are carried for insertion into a special manifold on the ventilation exhaust line. Each cartridge is able to generate in 50 minutes 53 cu. ft. of oxygen at atmospheric pressure. | |||||

| For C02 removal an improved system over that used on earlier submarine types has been installed. Two large chambers, each capable of holding 35 lbs. of a calcium compound (formula unknown), are placed in the recirculating line running to the small recirculating blower. See Plate I. It is to be noted that either or the main blowers can take a suction on this line, thereby making it possible with this arrangement to pass all or only a portion of the recirculated air in the vessel through these containers. 450 spare containers, each with 6.5 lbs. of compound for filling the chambers, are carried on board. An air flow meter and regulating valve is attached to the chamber so as to properly adjust the air flow through the line. | |||||

| The amount of air conditioning provided has proved inadequate for the warmer and more humid operating areas within the U.S. Operation of the U-2513 off Key West, Florida during the spring and summer months indicates the need for much additional air conditioning within the battery spaces and the maneuvering room. The high battery discharge and charging rates bring about this need for added cooling within the battery spaces and the resultant high power losses from the motors requires added cooling in the maneuvering room. | |||||

| The air conditioning system installed is of little interest except for the technique evolved to use it for heating the air. The piping and valves in the freon system have been arranged so that the air conditioning coils and condenser can be used interchangeably. A technique similar to this, but with the use of a second expansion valve, was installed on early U.S. submarines. This has since been abandoned because of the added piping and valves required, the operational difficulties encountered and the continued need for individual heating units in the various compartments. | |||||

- 3 - |

|||||

|

||||||||||||||||||||

| The adjustable cover installed over the natural supply to the batteries has some merit. It permits regulation of the supply air and allows rapid closing in case of a fire in the battery. | ||||||||||||||||||||

| 3. Individual Components | ||||||||||||||||||||

| a. Main ventilation blower characteristics: | ||||||||||||||||||||

|

||||||||||||||||||||

| b. Recircualtion blower characteristics: | ||||||||||||||||||||

|

||||||||||||||||||||

| c. Air conditioning system characteristics: | ||||||||||||||||||||

|

||||||||||||||||||||

| 4. Conclusion | ||||||||||||||||||||

| The ventilation, air purification and oxygen renewal systems designs for the type XXI vessel meet the requirements for this newer type of submarine. However, it is believed that a battery blower should have been installed so as to provide independent control of battery ventilation. | ||||||||||||||||||||

| The improved CO2 removal technique permits a constant control of CO2 percentage within the entire vessel, a feature which is highly desirable on a submarine which must remain submerged for long periods of time. | ||||||||||||||||||||

| The amount of air conditioning provided may possibly have been adequate for the cooler operating areas around the North Sea and British Isles but would surely have provided unbearable operating conditions within the vessel during any prolonged operation within tropic or even semi-tropic areas. | ||||||||||||||||||||

- 4 - |

||||||||||||||||||||